What is ciphertext? Features of the ciphertext

What is ciphertext? Features of the ciphertext

What is ciphertext? Features of the ciphertext

Views: 0 - Post on: 29/09/2022

In construction works, people often create beam connections with bolts, nuts and welding. Besides, there is another kind of material that is the ciphertext. So what is ciphertext and what are the characteristics, we will find out right after the article below.

The concept of ciphertext

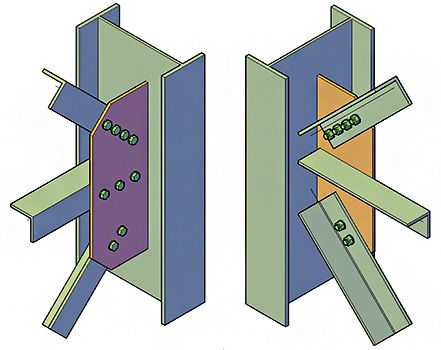

Gusset plate, also known as steel ciphertext, steel ciphertext, stair ciphertext, iron ciphertext, stone (as it is called in the South), .. The ciphertext is a steel plate welded into a box. square and placed at the top of the concrete pile. With the effect of welding to connect two concrete piles together during the process of pressing the pile into the ground. Or play the role of creating a fixed slab as an intermediary for bolts, screws, rivets, etc. to create fixed links between structures or support alignment in the design structure.

The board is used at bend points, joint positions or discrete connections to support stress transfer between parts participating in the connection. From there, it helps to strengthen the joints and also the grip force between them.

There are many methods to fix the ciphertext, the most common of which are rivets, bolts, welding or pressing.

We can find ciphertext widely used in the beam and column connection of bridges, used for the construction of house foundations, bridge foundations, buildings, .. or in many other construction structures in practice. .

Structure of the ciphertext

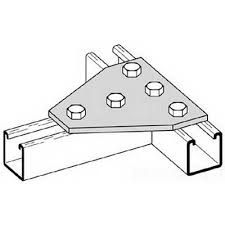

The ciphertext has a very simple shape and structure, the common ciphertext plates encountered in practice are usually square, rectangular or trapezoidal in shape. The surface is punched for the bolt to pass through.

In addition, you can also meet ciphertexts with triangles, circles, ovals or a custom shape that fits the joints, the edges of the column beams.

In general, the shape, size and thickness of the cipher plate depends greatly on the column beam design, force and load of the steel structure. So that it contains all the welding seams connecting the truss bar. And the angle between the ciphertext and the bar axis is not less than 15 degrees. To ensure the transmission of force from the rod to the cipher plate.

Therefore, in practice, the choice of ciphertext is calculated and selected very carefully based on the overall consideration of the properties of the work from the construction site (For example, the ciphertext used for the foot of the column or the slab). code used to bear the bolt connection), environment, construction location (Example: Location is dry or exposed to water), design of the building, requirements for bearing capacity of the structure, ..

Ciphertext materials

The ciphertext is usually made from cold rolled steel, stainless steel, galvanized steel, etc. In which, the galvanized steel ciphertext has high rust resistance, hardness and service life is also very high.

SS400 steel is a type of steel used to make cipher plates popular today. With high rigidity and tensile force, the connecting plate made of SS400 steel is specialized in the construction of pre-engineered steel buildings or industrial constructions.

In addition, to enhance ciphertext protection. After the installation is complete, the steel plate surface can be painted. As well as the entire steel structure of construction and architectural works.

Besides, the ciphertext can also be made of copper or aluminum (not common). And the ciphertext made of this material is usually only suitable for small structures that do not have high requirements for bearing capacity.

Notes on ciphertext steel in construction

– The width of the plate steel needs to ensure enough for the connection arrangement in terms of the length of the weld, the distribution of bolts on the surface.

– The thickness of ciphertext steel is determined based on the thinness and strength of the material. If the plate steel is too thick, it will destroy the bolt brittle. But if the platband is too thin, the bond failure will occur due to the ductility of the platband.

Methods of cutting ciphertext steel

There are many ciphertext cutting methods, each method possesses its own characteristics and advantages such as:

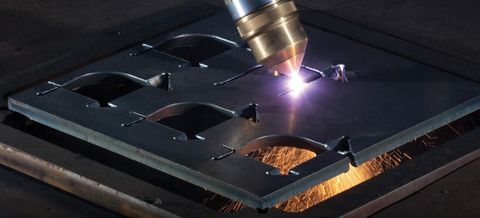

Cutting ciphertext by plasma cutting method

Is a cutting method possessing fast cutting speed, high productivity. But the disadvantage is creating a non-standard cutting line, the cutting edge of the section occurs with bevelling. The thicker the steel plates, the higher the chamfer is unsightly.

Cutting ciphertext steel by laser cutting method

Laser cutting is a method that uses a laser beam to shine directly on the surface of the part. To transfer heat to the inside. Causes a phase transition that melts or vaporizes the exposed part. To create voids on the surface of the part.

Laser cutting has the advantage of high accuracy and aesthetics. Less reprocessing required than plasma cutting.

Cutting ciphertext steel by oxy-gas cutting method

This is an old cutting method, capable of cutting very thick steel plates. However, this method has the disadvantage of creating high chamfers when cutting steel plates with large thicknesses.

Waterjet cutting method

Also called hydrodynamic method. This is a cutting method that uses water jet pressure at extremely high pressure to cut steel. This method has the advantage that the cut parameters are very small and smooth. The cutting process does not generate heat, so it does not deform the cutting material.

However, this method is quite “expensive”. Due to the cost of machine operation and processing costs are quite expensive compared to other cutting methods.